Hot Air Balloon Projects

For the start of Per Lindstrand’s new factory (Lindstrand Balloons Ltd) Aeromechanics was contracted to design a family of Natural shape balloons for the basic product range.

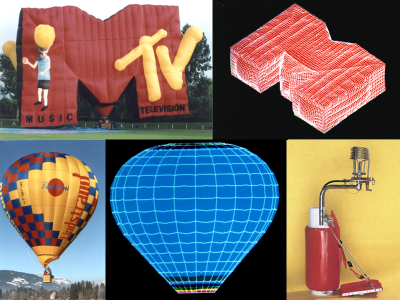

Although not strictly necessary for the design and certification of standard Hot Air Balloons, Aeromechanics used Finite Element Analysis techniques to predict the displaced shapes and stresses, the two lower left pictures refer. Comparison of the FEA data and the actual balloon help validate the material models and solution techniques. When comfortable with the correlation for the standard balloons Aeromechanics could use that criteria to predict the very much more complex behaviour of the special shape balloons.

The special shape ‘M’ balloon shown opposite in the two upper pictures should first be noted for the excellent correlation of displaced shape between the prediction on the right and the reality on the left. The pictures belie the significant solution effort required to attain convergence of the non-linear model.

Sometimes the simplest of Finite Element Models can be constructed in a very short time, the value of which can be significant when manually iterating to an optimal solution. The single seat cloud hopper (Picture bottom right) was just one such instance.